In a logical next step, Hatz Components GmbH started its activities as an independent company within the Hatz Group on December 1st, 2021. This also represents a clear statement on the production of high-quality, high-precision connecting rods for the future. The Components division has already written its very own success story in recent years and is now being formed into a mainstay of the parent company, Motorenfabrik Hatz. The success of the past few years will be continued and expanded under the umbrella of the new “Hatz Components” brand.

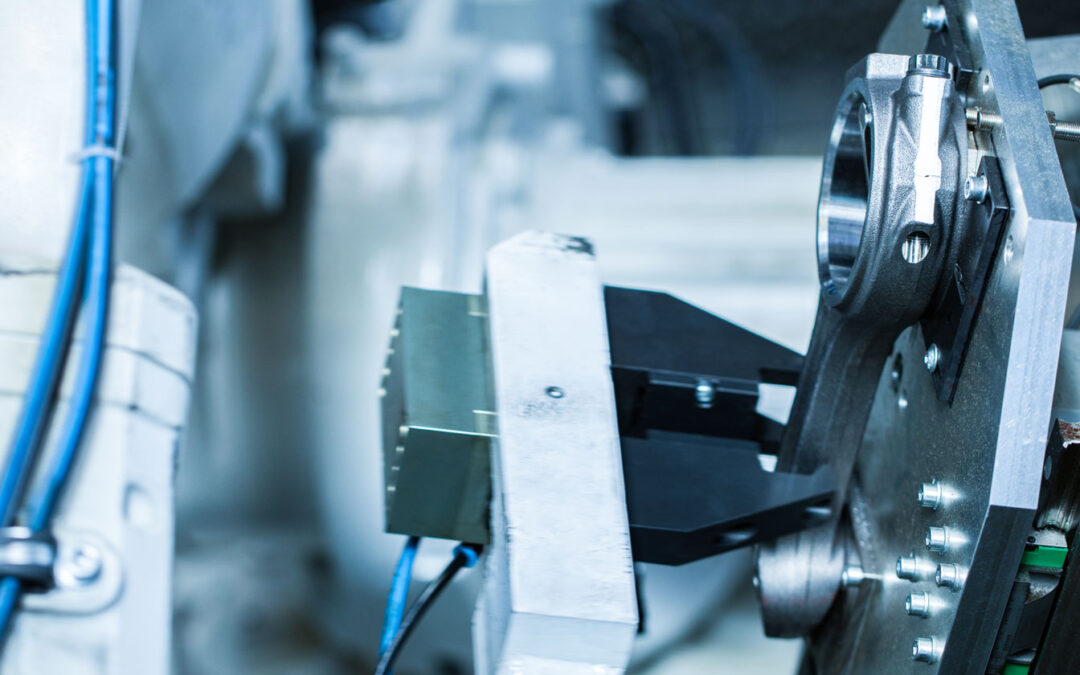

Hatz Components GmbH acts as a flexible one-stop specialist for connecting rods with a center distance of 100 to 350 mm, in applications such as small and large units from one to 24 cylinders. All cross-industry and customary requirements are mastered. Hatz Components mainly aims at on- and off-road applications. Today, connecting rods can already be found, for example, in recreational and agricultural applications as well as in engines of all kinds in the automotive and commercial vehicle industry and many others.

Customers all over the world trust in our quality

Customers all over the world trust in the quality of the connecting rods manufactured by Hatz Components. Our customers particularly value high flexibility in quantities and production, precision, delivery reliability and smooth development cooperation.

All markets and regions

With a clear commitment to combustion engines, Hatz Components serves all markets and regions of the world. The focus is on the existing and growth markets in aggregate construction in the EMEA, NAFTA, LATAM, APAC, AMEA and EMEA regions.

We can look back on a total of more than 140 years of engine history and more than 40 years of experience in the external component business. Our customers in the components business have already given us countless awards for our performance with regard to important criteria such as delivery reliability, quality and many more. The most important quality feature are satisfied customers. Hatz is classified as an A supplier by all customers.

Passenger Car Manufacturers are increasingly outsourcing the in-house production of components

An overall promising project for the future: the current reorientation of the automotive OEM is having an indirect positive effect on the future prospects of component production. The focus of the automotive industry on electric drive solutions and the resulting reduction in components relevant to combustion engines in automotive OEM in-house production is increasing the volume on the free market. As a result, reliable partners with great expertise and excellent production quality are still in great demand. This applies in particular – and especially now and in the future – to Hatz Components.